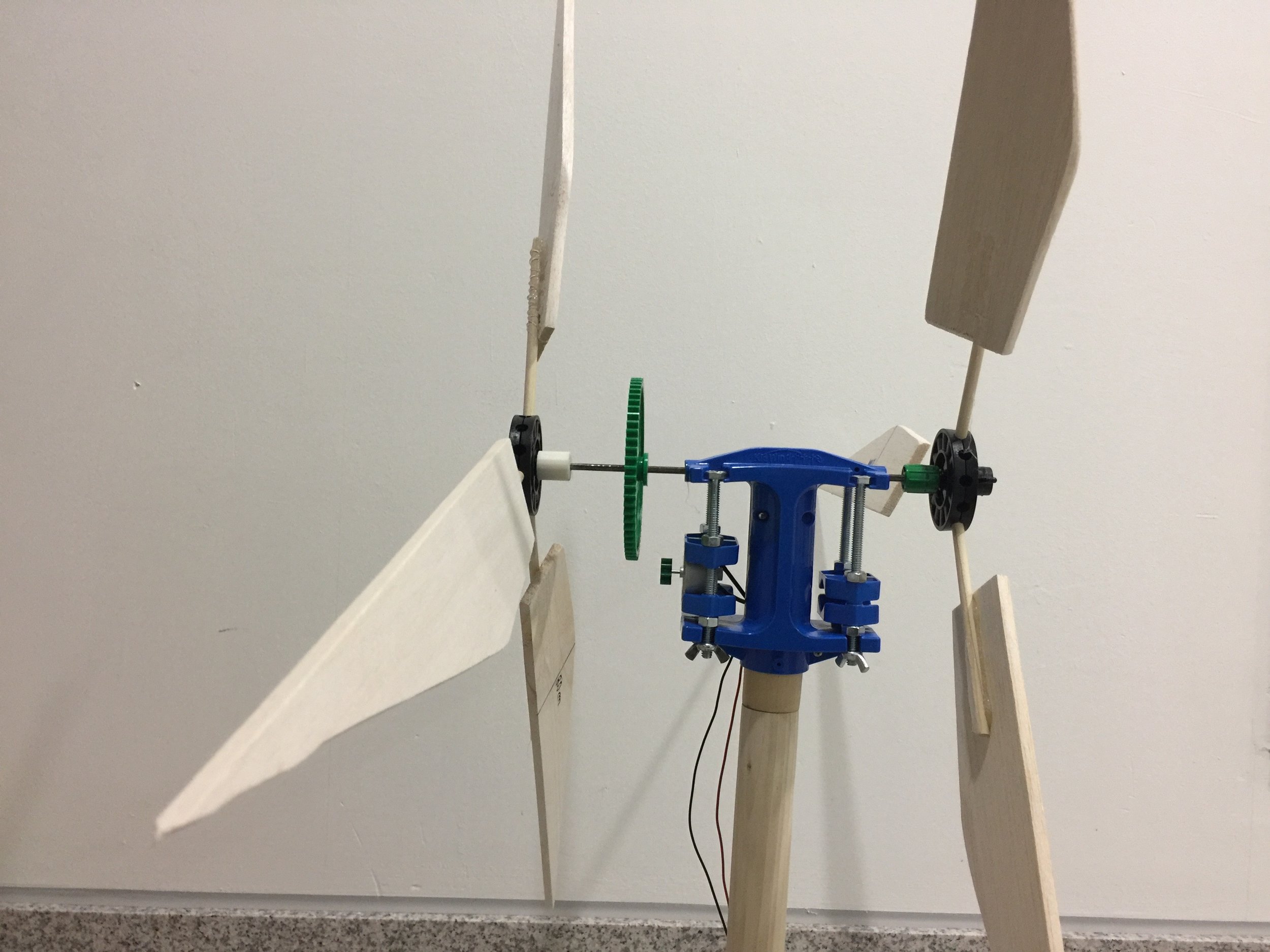

For an upcoming interdisciplinary unit on wind turbine design, the main focus was collecting reliable data to inform iterations of the design. The best way to gather accurate data is to have reliable testing conditions. So we decided to build a Wind Tunnel Test Chamber.

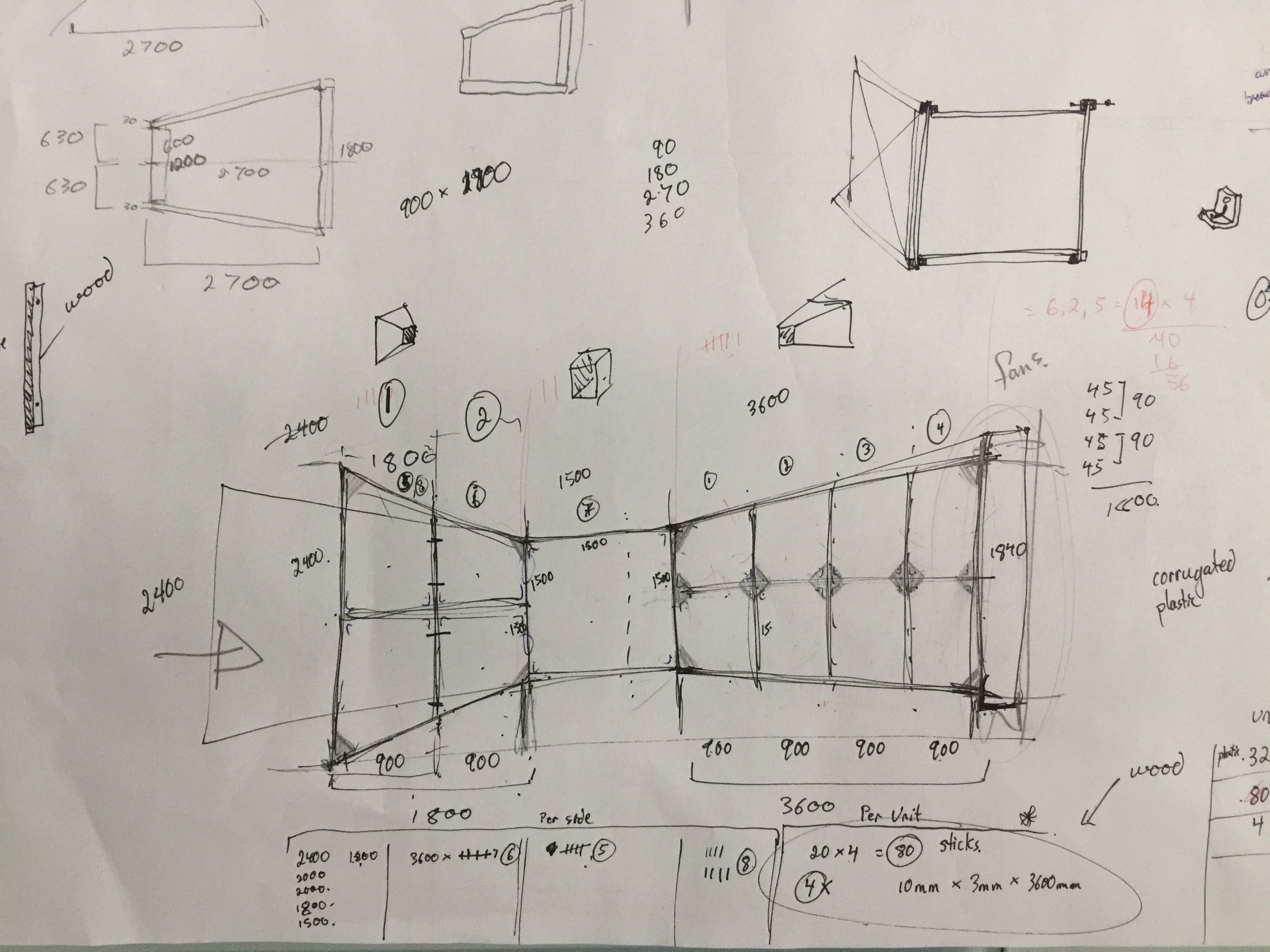

Along with a team of grade nine students and a couple of teachers, we constructed a 3-part test chamber. Our first discovery in our research was that wind tunnels pull air, not blow air. This produced laminar flow, which has very low turbulence, and hence, a consistent wind speed at the contact surface of the blades.

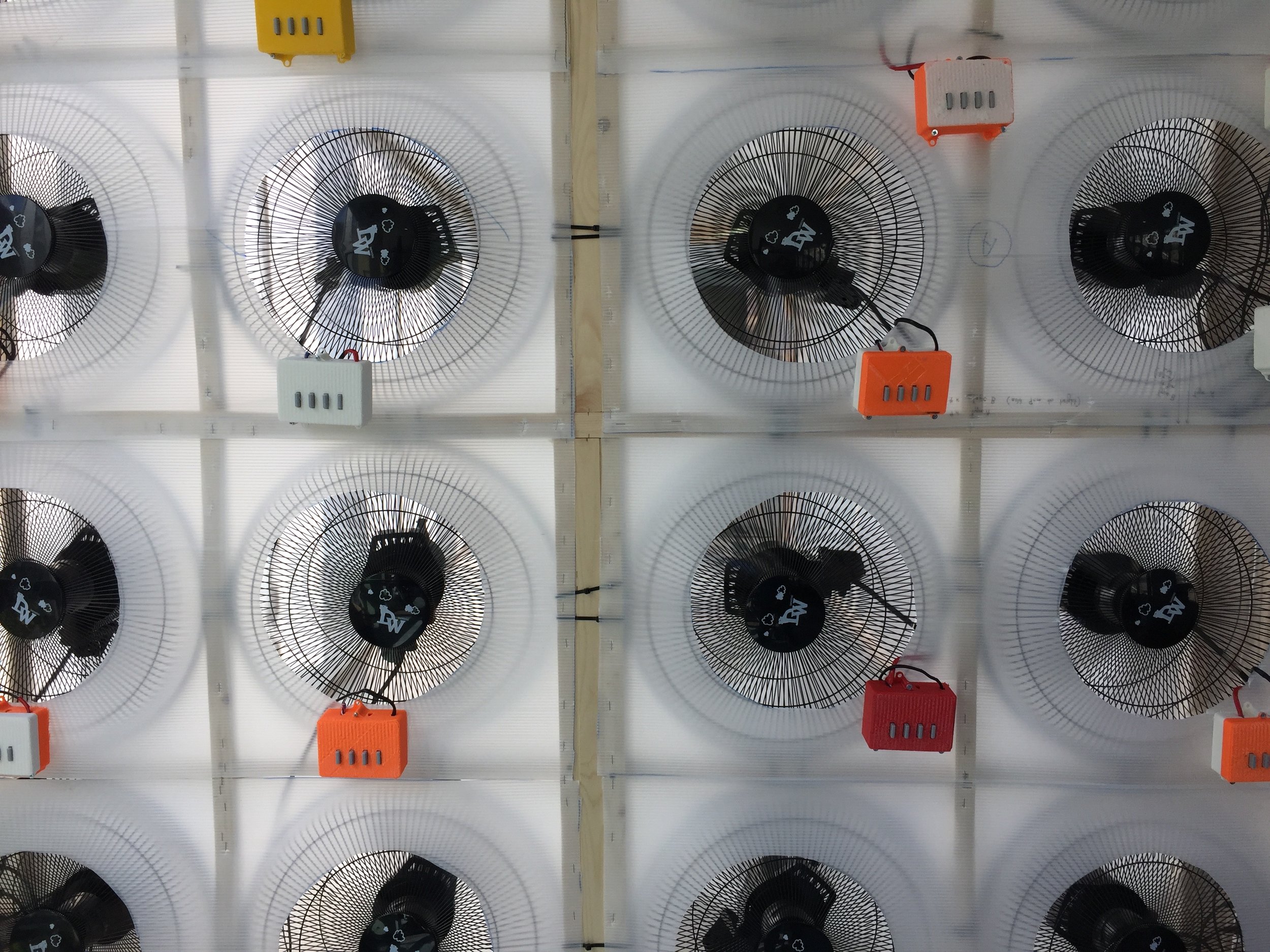

Using what we had, we "re-purposed" some standing fans to build a wall of 16 fans to pull air into the chamber. New power boxes were 3D printed to contain the switches and wires we harvested from the fans. The 1.2 meter square test chamber was equipped with an anemometer to measure windspeed right in front of the prototypes.

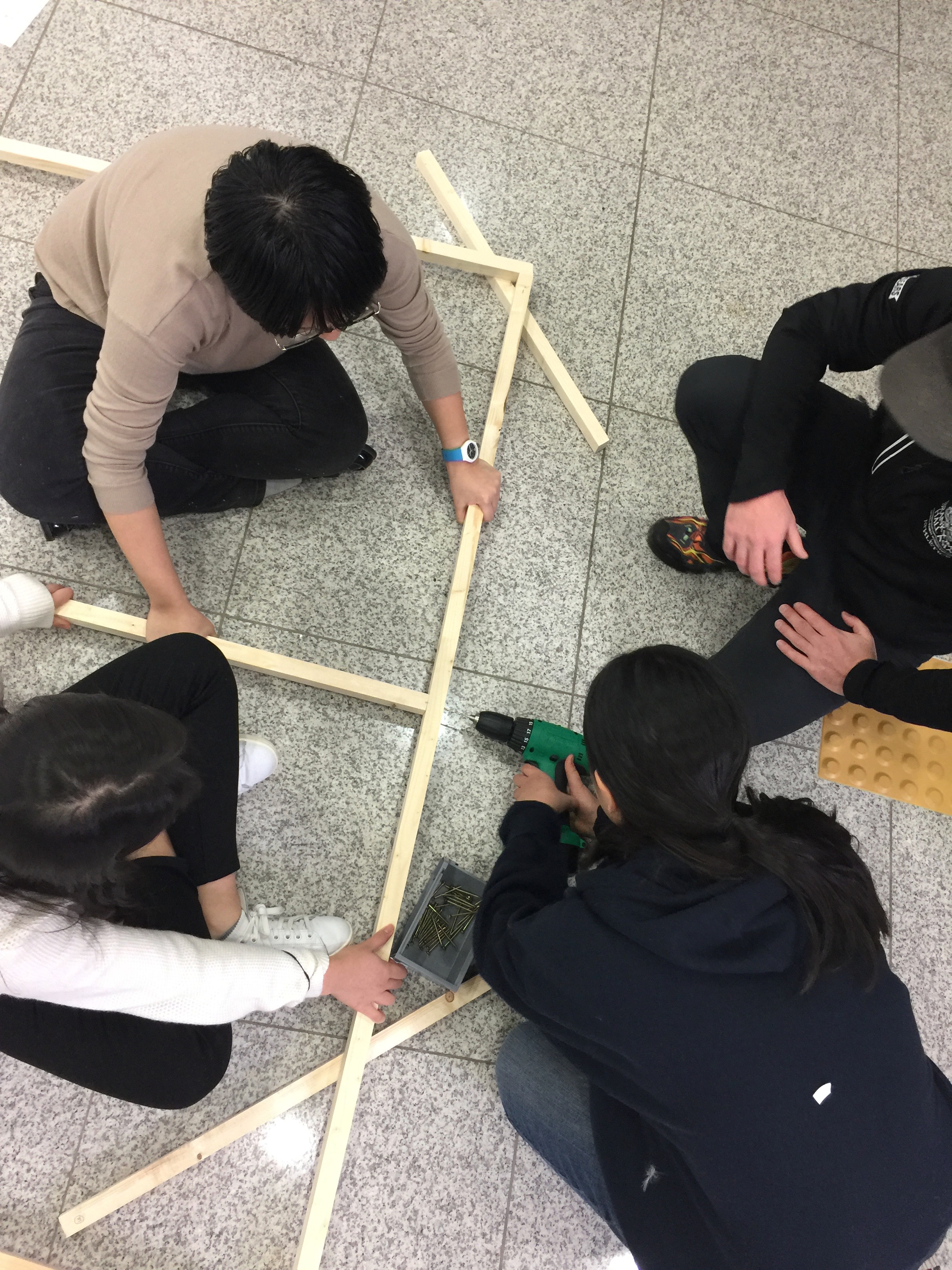

The frame was built of wood, with corrugated plastic sheets used for the panels. The corrugated plastic is very light and easy to work with.

Working alongside the grade nine girls, it was rewarding to see them develop their skills, confidence, and pride in working at such a large scale. It was a great opportunity for them to practically apply their geometry knowledge on a large scale and through manipulating materials.